OEM or Systems Integrator for Factory Automation

Successful manufacturing companies recognize the benefits of automating critical processes. Quality Control, Lower Costs and Employee Health & Safety are major motivating factors to automate. Some manufactures keep automation projects in house because of trade secrets and highly technical processes with steep learning curves. Unless there is a specific reason to keep an automation project in house, it makes sense to use an outside firm for some or all of the project.

There are two main options when hiring an outside company to automate a process.

- OEM (Original Equipment Manufacturer)

- SI (Systems Integrator)

Click Here to continue article.

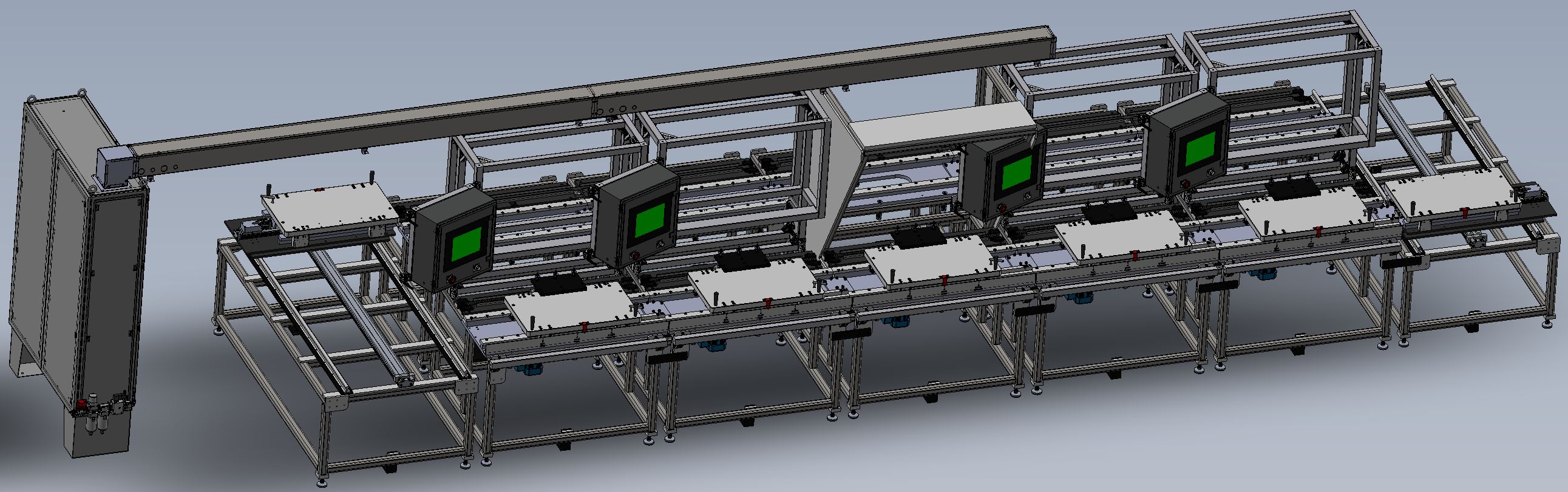

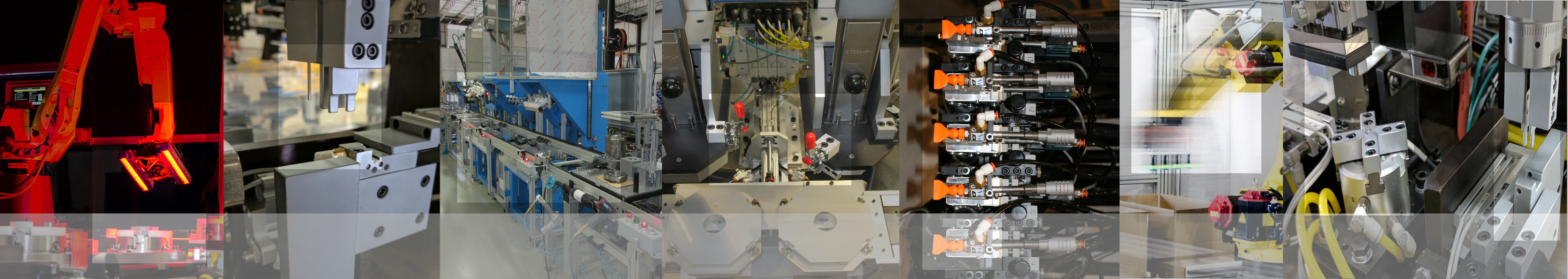

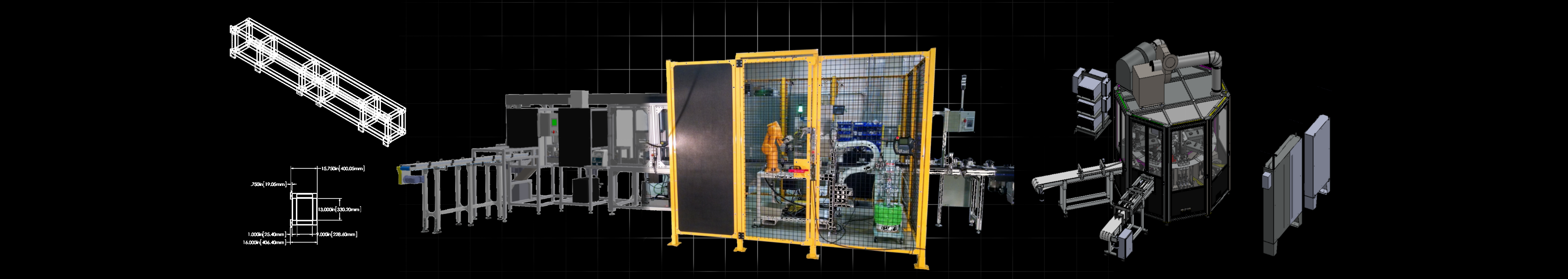

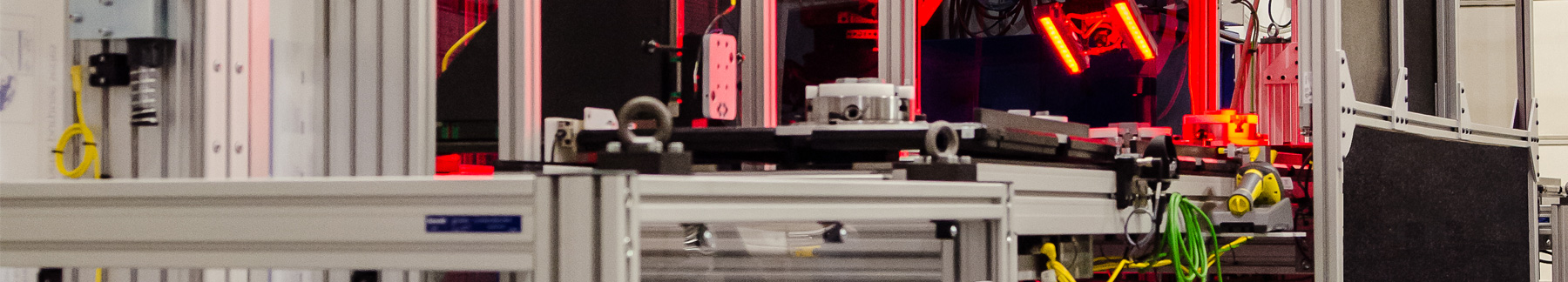

ProMATIC Automation is capable of automating a wide range of processes. We have nearly 20 years of experience automating these processes across a diverse cross section of industries like Automotive, Bio-medial, Manufacturing, Industrial, Heavy Construction, Commercial/Industrial Lighting, Hydraulic Power and Plastics Injection Molding.

- Assembly

- Inspection

- Dispensing

- Machining

- Electrical Testing

- Palletizing

- Locating

Watch this video to see an overview of the types of projects ProMATIC Automation has automated.

OEM

An OEM is best suited to perform a task with a narrow focus. They are an expert in a specific field. For example, if the automation process requires dispensing a precise volume of material or measuring a specific parameter, an OEM is a good choice. They know how to do one thing and do it well.

Utilizing an OEM will require some level of in house assistance. At a minimum, the manufacturer will need to provide electrical and pneumatic service and mounts for the equipment being installed. If the equipment is physically large, like a new conveyor system, in house engineering will be required for facilities layout and provide rigging to place the equipment. Additional in house resources may be required depending on the complexity of the automation.

The staff for an OEM will be experts with in depth knowledge about their product. They will know how to assemble it, set it up, program it, debug it and use it. They will not be effect in assisting with the setup of interfacing equipment.

Systems Integrator

A systems integrator has a much broader scope. Systems integrators design and build custom automated machines to accomplish a wide variety of processes.

- Assembly

- Material Handling

- Packaging

- Part Feeding

- Welding

- Painting

- Electrical Test & Monitor

- Dispensing

- Vision Systems

Many systems integrators have been able to capitalize on experience they have gained by designing and building custom machines to carve out a niche. In effect becoming a specialist in one or more areas while continuing to offer broad automation capabilities. A few examples of niche specialties are welding, soldering and special material handling capabilities.

A systems integrator staff will include multiple specialists in one area of expertise.

- Controls Engineer

- Mechanical Engineer

- Fabricator

- Tool Maker

- Assembler

Each position is essential but a key position for a systems integrator will be the controls engineer. The controls engineer will be with the system for the life of the project. Custom automation requires specifying multiple pieces of equipment. The controls engineer selects, configures and programs all equipment to work together and communicate with the customers existing equipment.

DIY or Outsource

Prior to contacting an outside firm, the process needs to be well defined so a supplier can give the most accurate quote and avoid job over runs and change orders. If a manufacture decides to keep all or part of the automation project in house, contacting an outside source can still be helpful in terms of determining costs and alternate manufacturing processes.

Outsourcing automation may have other benefits as well. An outside prospective will help avoid tunnel vision. Both OEM’s and SI’s are constantly exposed to the newest technology and equipment. They can offer better alternate ways to accomplish the goal.

Once a manufactures process has been well defined, getting a quote should be straight forward. Once the quoted cost to automate is known, an informed decision can be made about proceeding. It isn’t uncommon for an OEM to submit a “no quote” because the project does not meet the minimum revenue threshold or perhaps the project is to risky. Even if they submit a no quote, it will offer a the manufacture an expert opinion on whether or not the process should be automated.

When comparing costs an easy factor to over look is shipping and installation. Choosing an equipment provider in close proximity has cost savings benefits. They can offer quick onsite assistance after the install. If the system is large and requires a crew to install, there are cost savings from not having to pay for travel, meals and lodging. When there is not a local OEM or SI, then keeping the project in house may be less expensive.

Taking time to develop a relationship with a local OEM or SI can payback in multiple ways. Manufactures should always meet with an OEM or SI before deciding to keep a project in house.