Custom Configurations

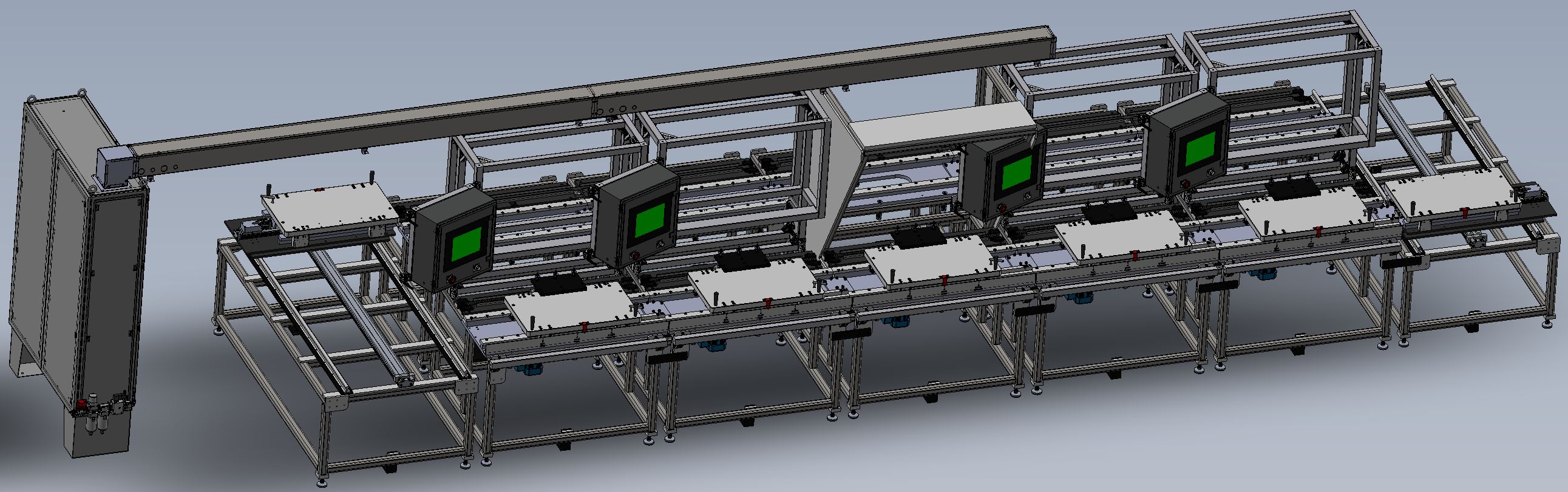

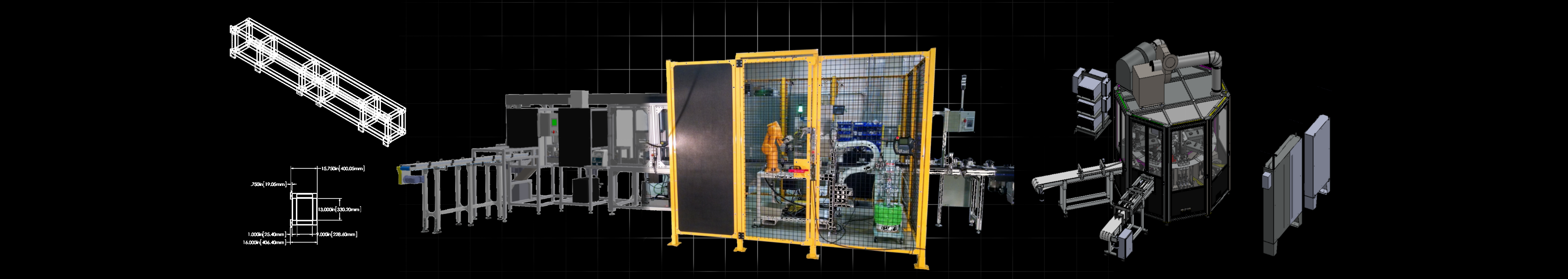

Parts Handling:

- Synchronous and non-synchronous lines

- Multi-station, palletized power-and-free conveyor systems

- Walking beam configurations

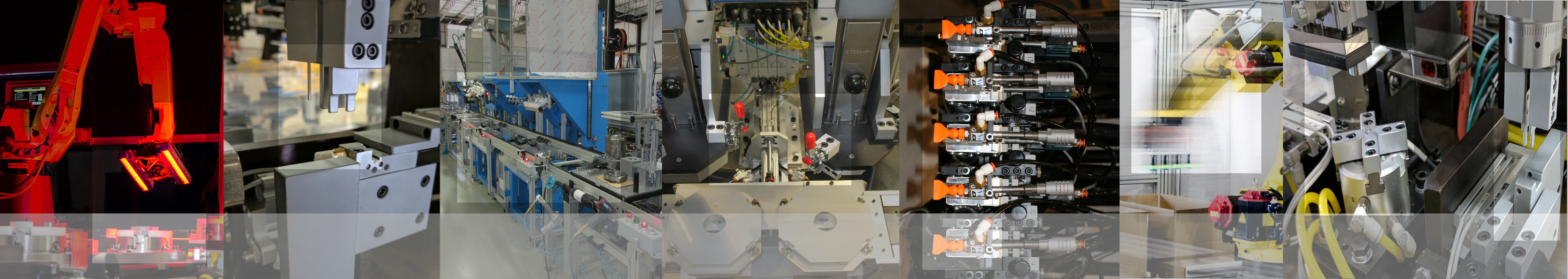

- Pick and Place devices with vacuum and gripper tooling

- RFID and Bar Code Scanning (hand-held and stationary)

Custom Operations:

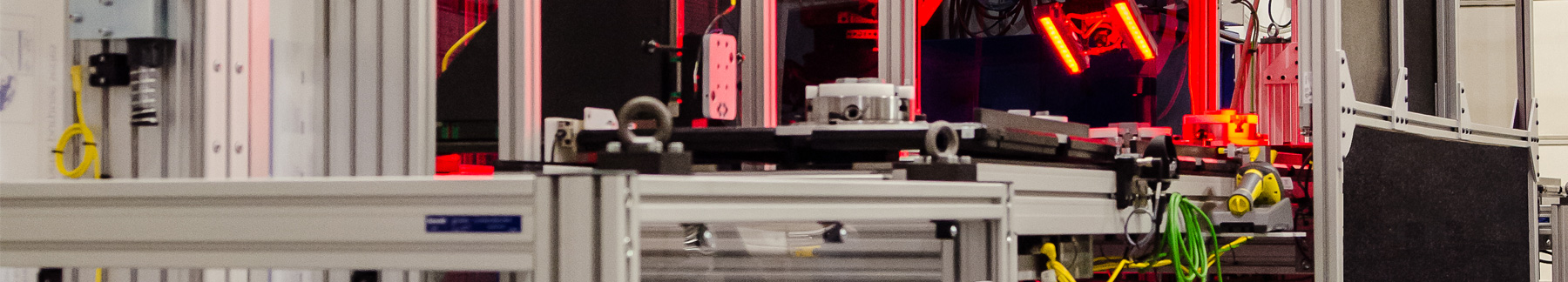

- Robotics (loading/unloading/ assembly/dispensing)

- Servo-press

- DC Torque Application

- Automatic Parts Feeding (vibratory)

- Vision Inspection

- Pick-to-light Operator Assembly

- Laser/LVDT Measurement

- Dispensing Systems (Adhesives, Lubricants, etc…)

- Leak Testing (mass-flow and pressure-drop)

- Electrical Testing

Customized Controls

- PC and PLC Control with multiple HMI (Human Machine Interface) locations provide Data Tracking capability and detailed operator instructions and fault messages for troubleshooting the assembly process.

- Multiple Controls platforms are available (Allen Bradley, Siemens, GE, AutomationDirect, Omron, etc…) as well as multiple HMI brands.

Watch this video to see an overview of the types of custom projects ProMATIC has automated. Click Here to view videos of additional custom projects.