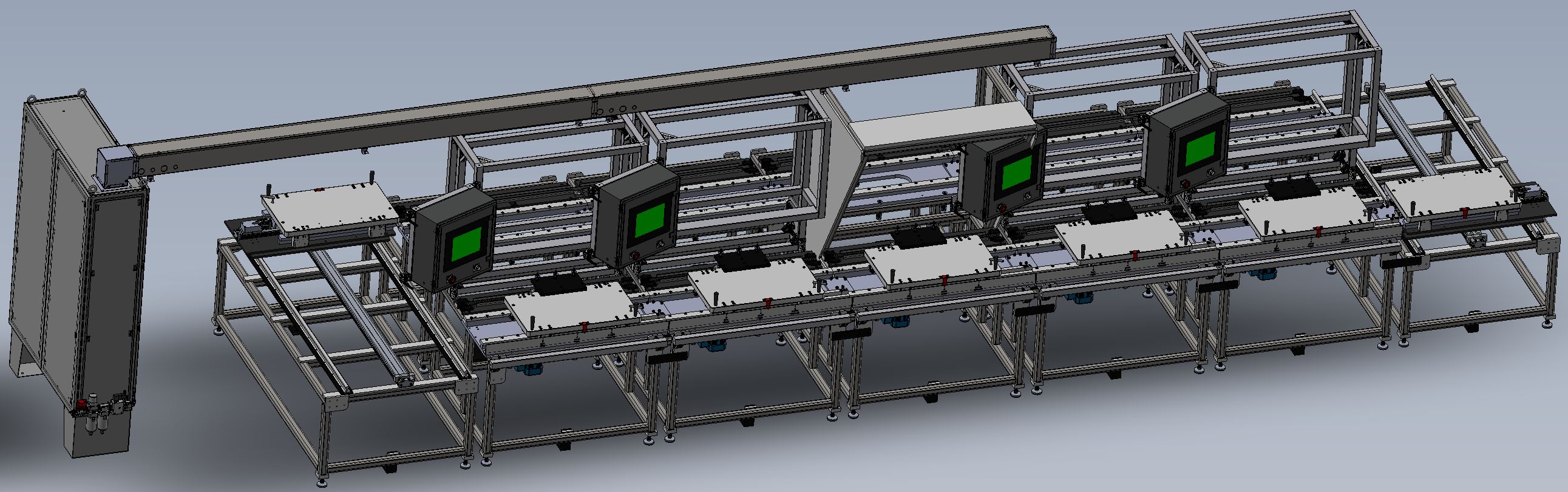

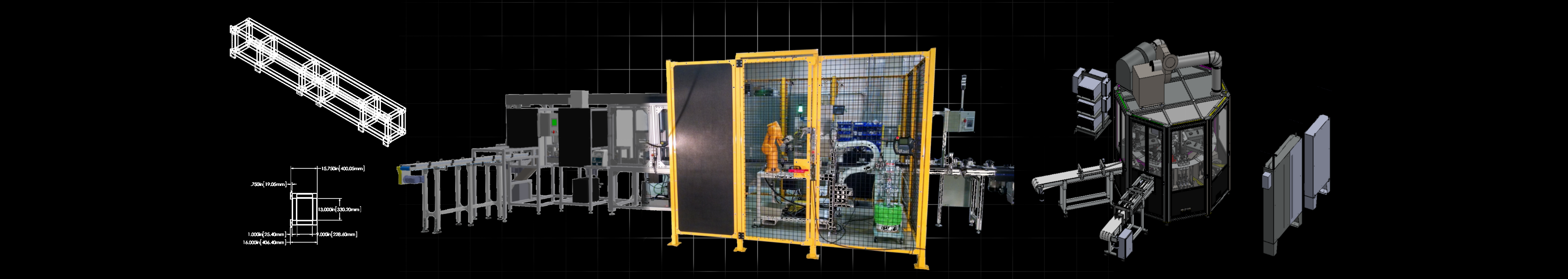

Assembly Lines

Parts Handling:

Parts Handling:

- Synchronous and non-synchronous lines

- Multi-station, palletized power-and-free conveyor systems

- Walking beam configurations

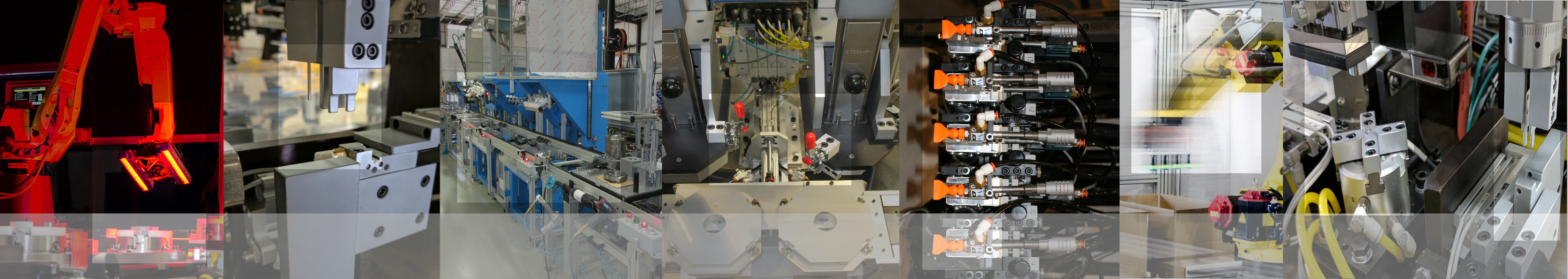

- Pick and Place devices with vacuum and gripper tooling

- RFID and Bar Code Scanning (hand-held and stationary)

Station Configurations:

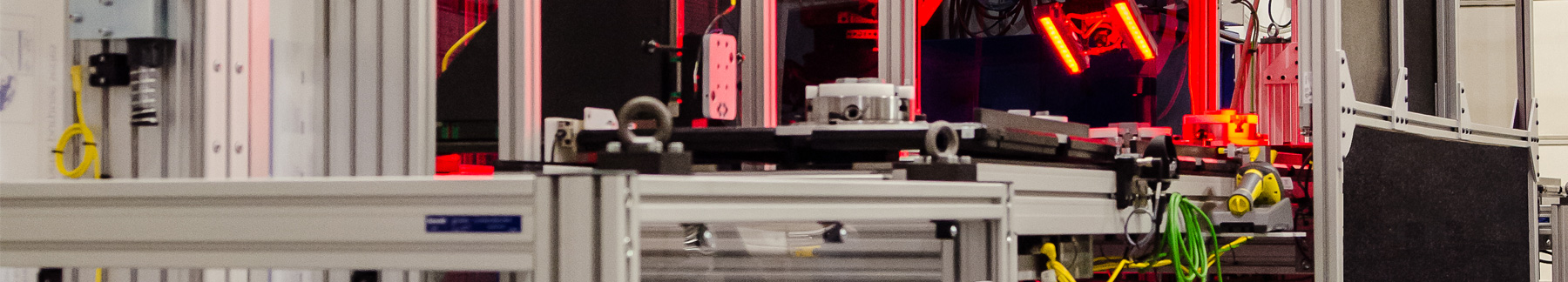

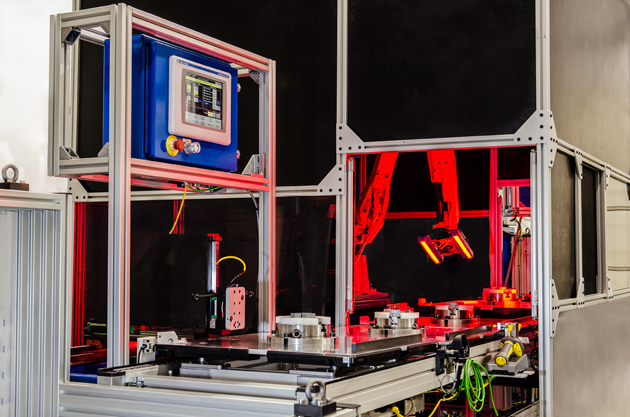

- Robotics (loading/unloading/ assembly/dispensing)

- Servo-press

- DC Torque Application

- Automatic Parts Feeding (vibratory)

- Vision Inspection

- Pick-to-light Operator Assembly

- Laser/LVDT Measurement

- Dispensing Systems (Adhesives, Lubricants, etc…)

- Leak Testing (mass-flow and pressure-drop)

- Electrical Testing

Control Configurations

- PC and PLC Control with multiple HMI (Human Machine Interface) locations provide Data Tracking capability and detailed operator instructions and fault messages for troubleshooting the assembly process.

- Multiple Controls platforms are available (Allen Bradley, Siemens, GE, AutomationDirect, Omron, etc…) as well as HMI brands.

- Designs are done with ergonomic and safety considerations for each operation.

Watch this video to see an overview of the types of projects ProMatic has automated. Project videos also available – Click Here to view them.