Our Project Approach

At ProMATIC, every project presents a new and interesting challenge that allows the team to use their strong, creative spirit to deliver the most robust, repeatable and cost-efficient solution.

THE PROCESS:

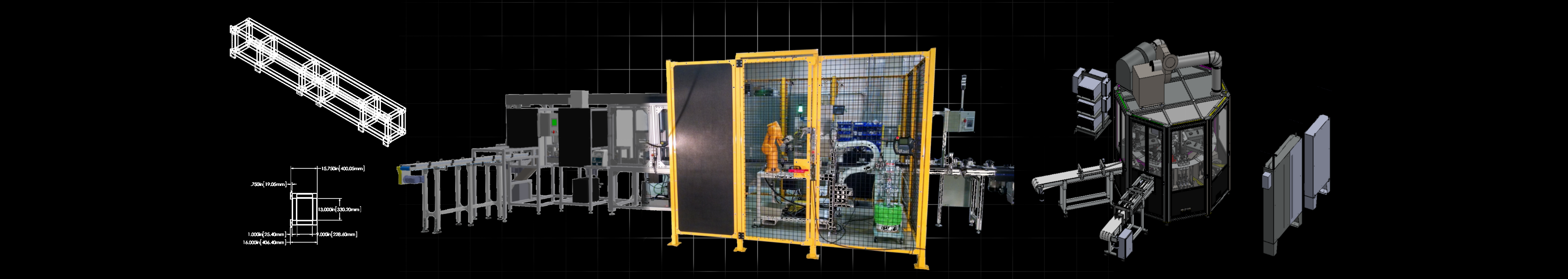

Concept Design/Quotation

The machine concept phase of the design and quoting process is taken as the most important with involvement from all disciplines including customer representatives. ProMATIC Automation, Inc. will provide a detailed and comprehensive Quotation for your Custom Machine according to your specifications.

Project Management

Each project at ProMATIC is managed on a daily basis allowing the customer to get project status information as often as needed. Weekly project schedules are emailed with status updates to the customer with web-ex meetings and phone conferences encouraged as more information is needed.

Any revisions or changes are handled with a Change Order that is fully documented and approved by all parties involved in the project as appropriate. Any effect on overall cost or delivery due to the change order is agreed upon at the time of approval before work on that particular item is begun.

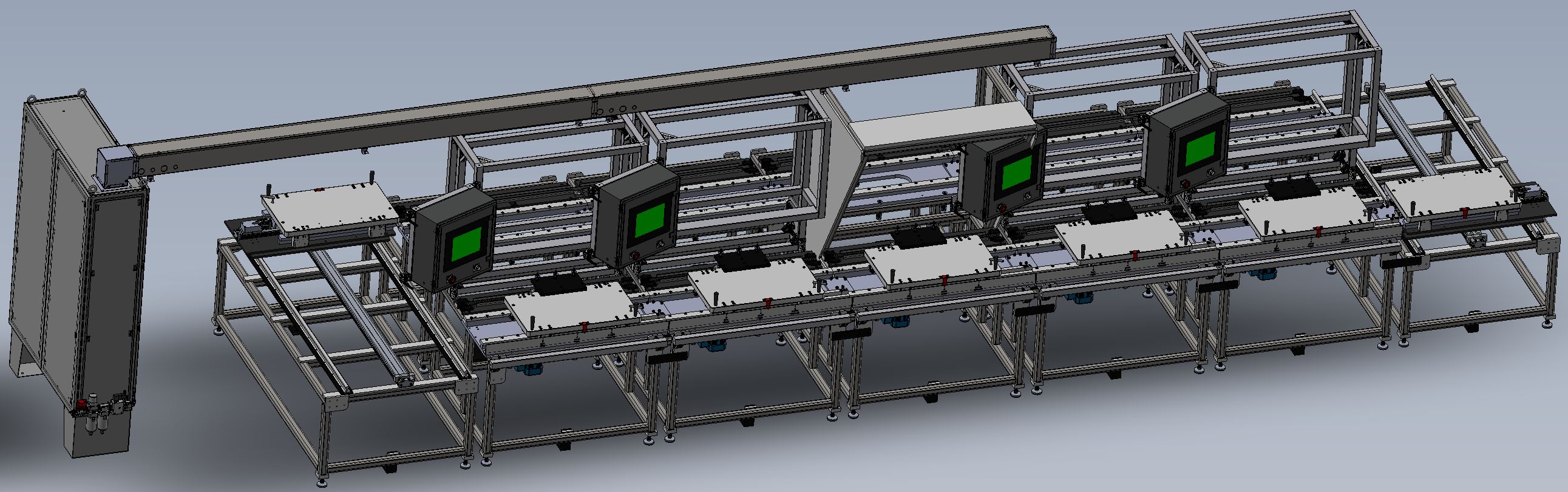

Design and Programming

Mechanical Design is done using 3D Solidworks. Programming is done using multiple controls platforms (PC or PLC) with a focus on simplicity, safety, and fault recovery. Multiple Design Reviews and frequent customer interaction and involvement in the design and build process are the normal mode of operation at ProMATIC.

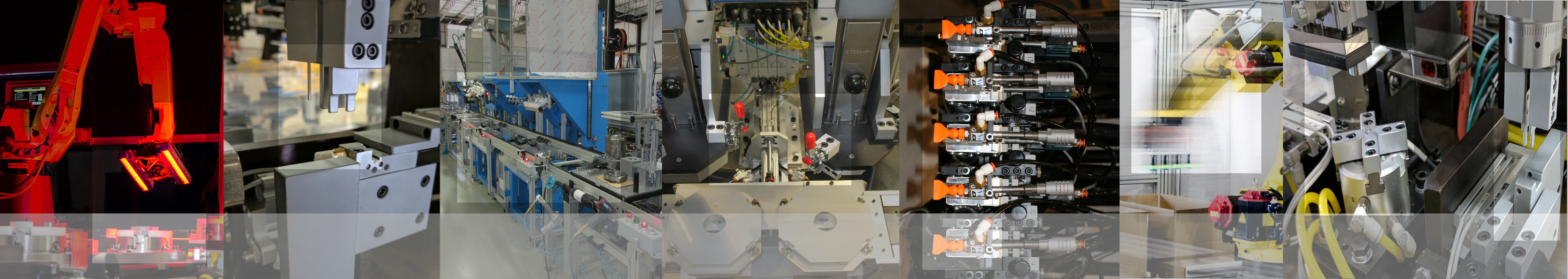

Machining and Fabrication

After detail design is complete, a drawing package is released to in-house fabrication and machining. Raw material is ordered and the construction process begins. ProMATIC utilizes expert welding and fabrication personnel to build machine frames and weldments of all types materials. Custom designed parts are machined to specific tolerances with CNC machining equipment. Each manufactured component is finished (painted, plated, etc…) according to the specific machine function of that component and according to customer specifications. Finished parts are internally inspected for drawing and specification compliance.

Procurement

Any automation system produced by ProMATIC is a combination of precision manufactured fabricated and machined components along with purchased automation components provided by leading automation suppliers respected in the industry. This includes robots, vision systems, lasers, sensors, measurement devices, dispensing equipment, pneumatic and hydraulic components, electrical and control components, as well as other automation technologies. ProMATIC has strong supporting relationships with the vendors that supply these high-tech automation technology components. Material orders are placed on-time to ensure the components are received at the proper time according to the overall build schedule. Long-lead components are tracked and managed closely to avoid delays in the machine delivery.

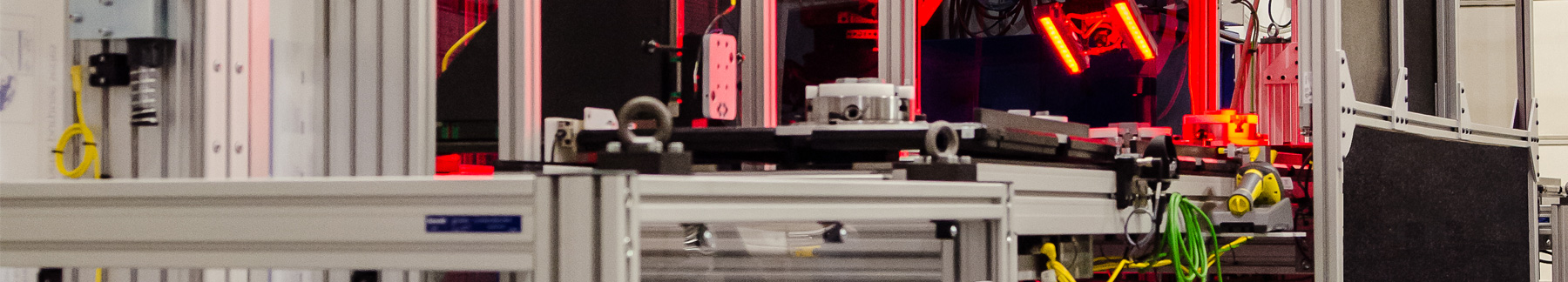

Assembly

All fabricated, machined, and purchased components are assembled on the floor at ProMATIC by highly-skilled mechanical and electrical technicians with many years of machine building experience. Workmanship and attention to detail is the daily focus during the assembly process. Customers are invited to visit ProMATIC at any time during the assembly process to observe the system construction at any stage of the build.

Equipment Demonstration and Run-off

After Final Assembly and Debug is complete, an Equipment Run-off (Acceptance) will be done at the ProMATIC Automation Inc., facility to verify that the equipment meets the intended specifications. The presence of customer engineer(s) and assembly operator(s) as well as appropriate ProMATIC Automation Inc., personnel is requested. During this demonstration, the operators will become familiar with the machine control, system components, and maintenance procedures.

Delivery/Installation/Service

ProMATIC provides complete turnkey installation services and cooperates with the customer in the set-up of the equipment in the customer’s facility to get the system to production capacity. We also provide on-site training and support at the time of installation. ProMATIC Automation, Inc. personnel are available throughout the life of the equipment for service needs and warranty issues will be responded to promptly.

Documentation

At the end of each project a complete Documentation Package is provided with all machine assembly drawings and schematics as well as purchased component literature, Spare Parts Lists, and Maintenance/Troubleshooting information.