ProMATIC Installs India Automation

In January 2017, ProMATIC Automation completed it’s first installation in India. The installation team finished ahead of schedule. John Fisher, the project manager, coordinated the packaging of the equipment and shipping of the containers. Each machine section was palletized and individually sealed in a Mylar film. Industrial desiccant packs were sealed inside the Mylar as a preventive measure to combat rusting while in transit.

Click Here to continue article.

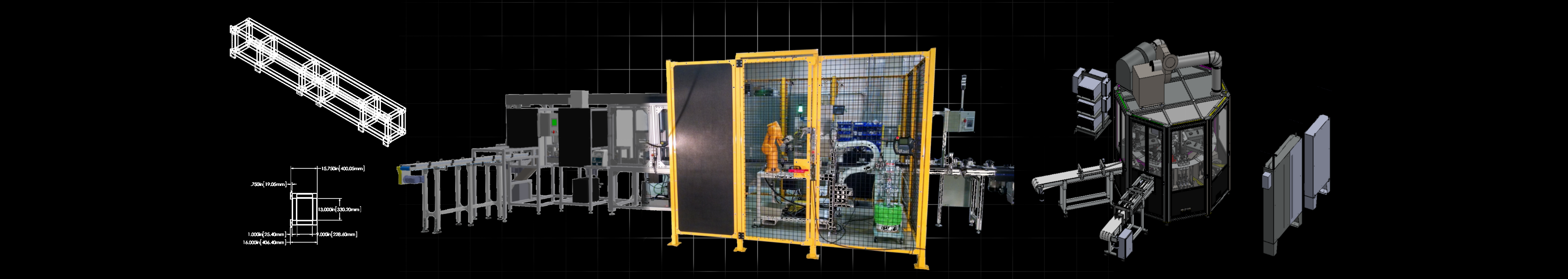

ProMATIC Automation is capable of automating a wide range of processes. We have nearly 20 years of experience automating these processes across a diverse cross section of industries like Automotive, Bio-medial, Manufacturing, Industrial, Heavy Construction, Commercial/Industrial Lighting, Hydraulic Power and Plastics Injection Molding.

- Assembly

- Inspection

- Dispensing

- Machining

- Electrical Testing

- Palletizing

- Locating

Watch this video to see an overview of the types of projects ProMATIC Automation has automated.

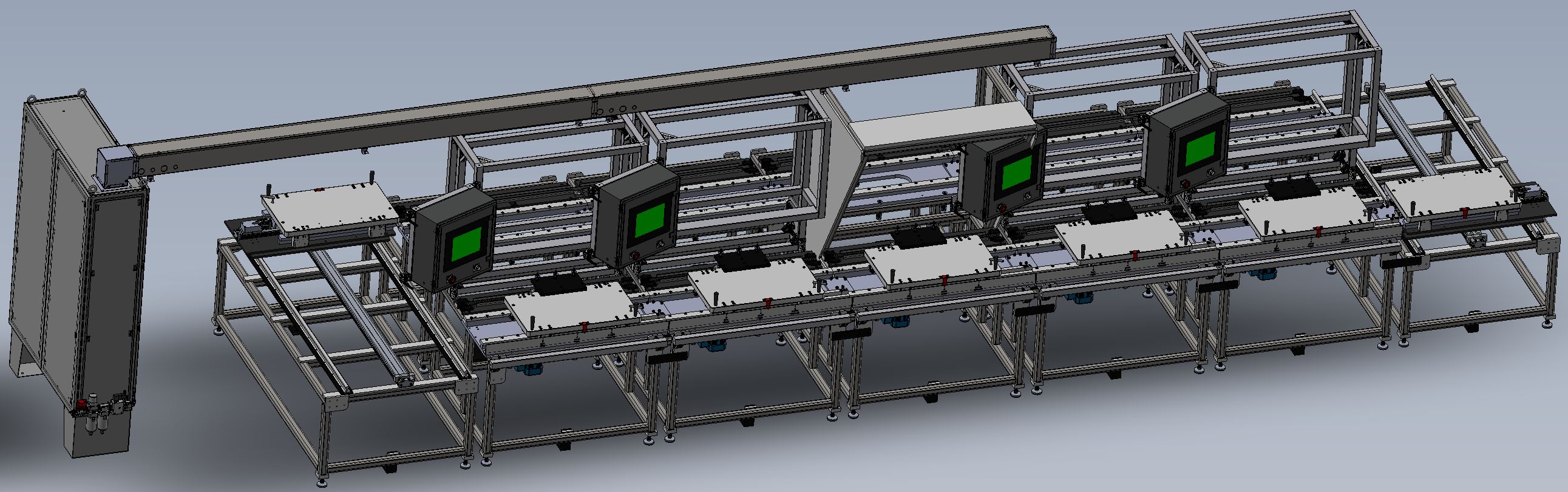

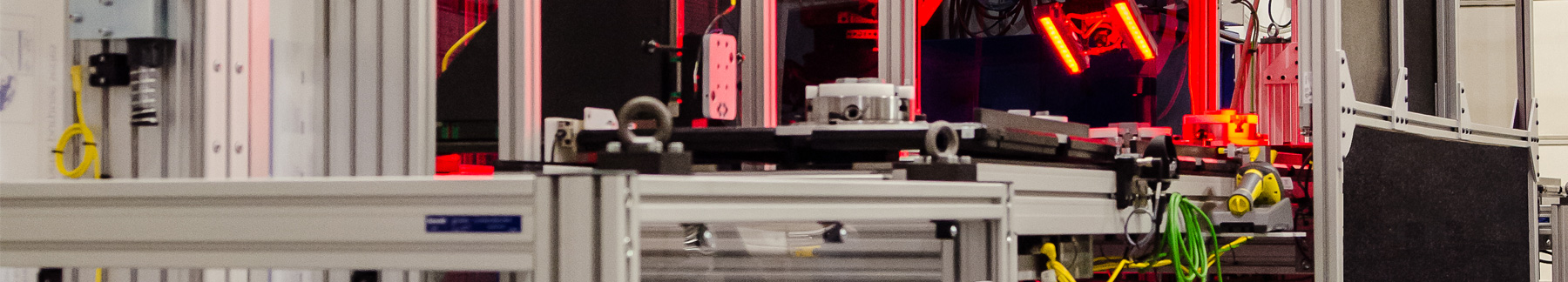

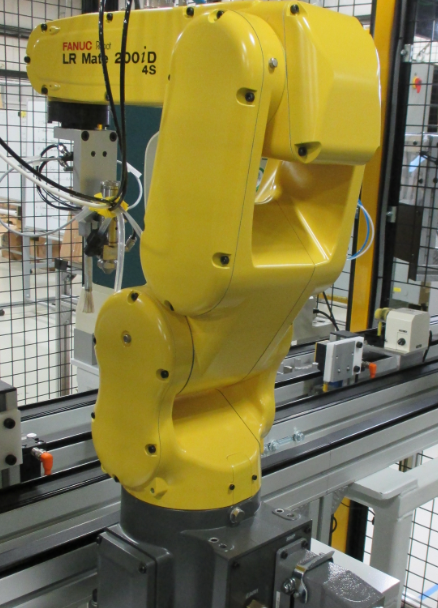

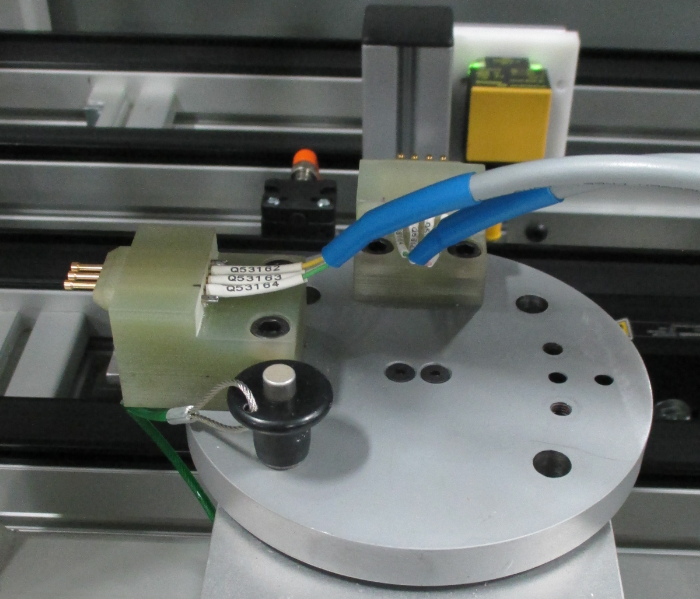

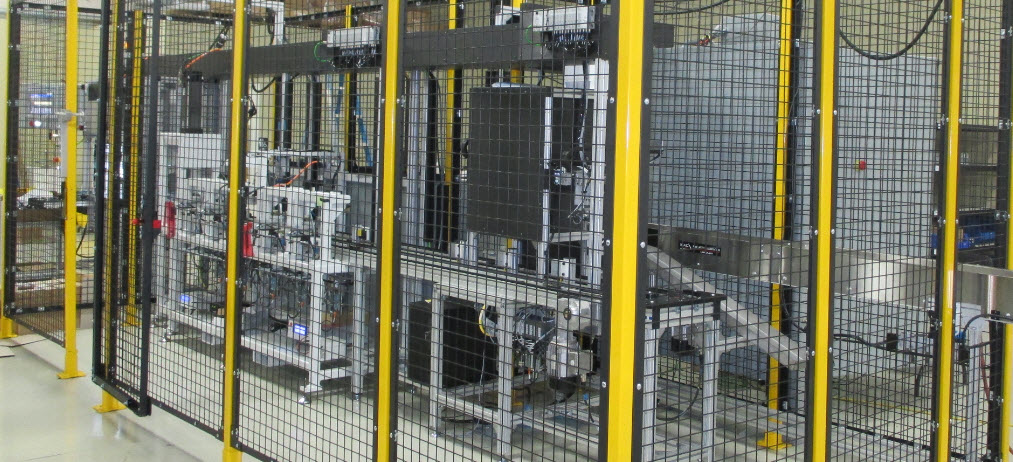

The system was a combination of work cells, semi-automatic stations and fully automated operations. The system was designed around a Bosch Rexroth palletized conveyor system. A few of the main integrated components were a 3-axis Apollo Seiko soldering robot, a Fanuc 5-axis robot, a vacuum dispense system from Exact and Heller forced convection reflow oven.

After the installation was compete the startup team was on site to tweak the system. They provided support to the customer as they trained for an additional week.

Congratulations to the team for another successful install!